Efficient Project and Portfolio Management: More Success through Structured Planning

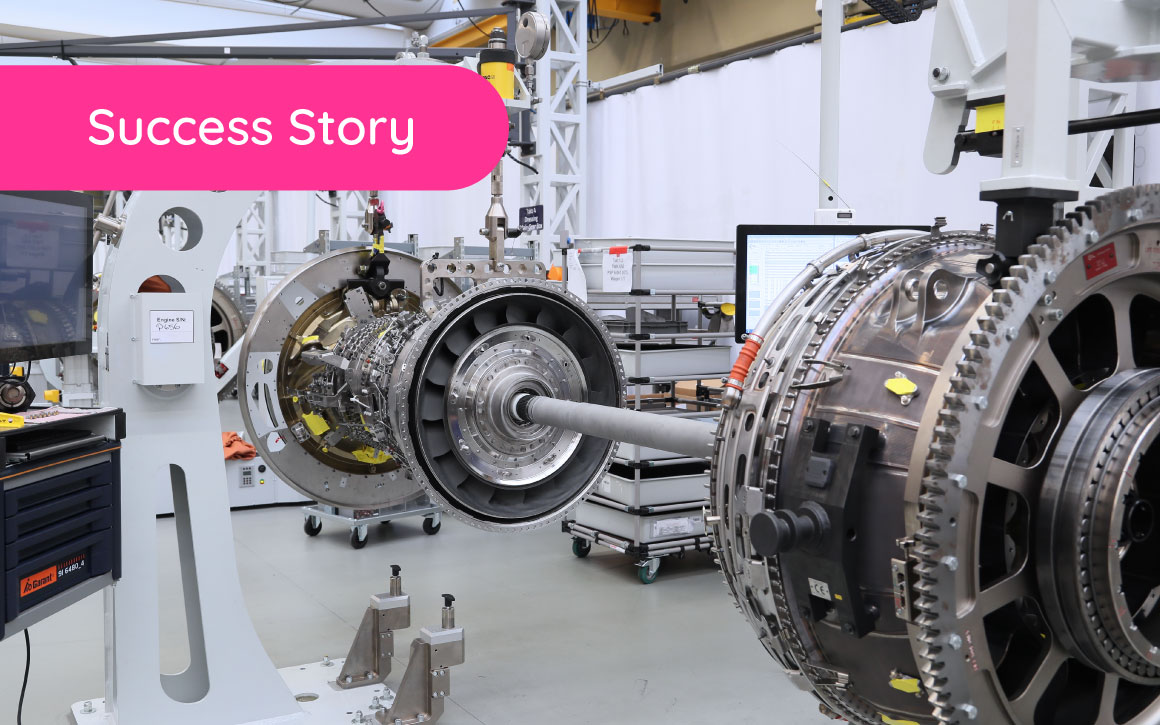

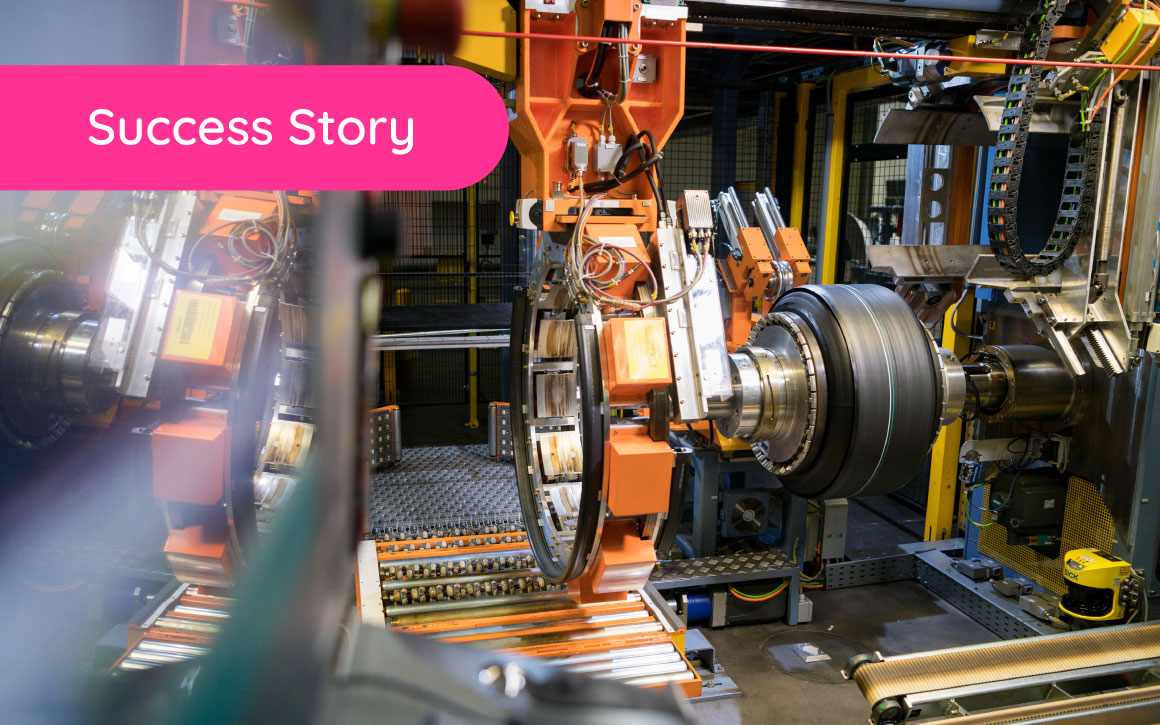

Mechanical engineering is a highly complex industry in which the development and manufacture of machines and systems involves a high degree of technical expertise. This requires close cooperation with the various specialist departments to ensure that the project is completed efficiently and successfully.

Request demoThese and More Companies Trust in cplace

cplace has proven to be a user-friendly, lean, and flexible solution. We were determined to avoid being dependent on a provider offering a custom-developed solution in a “black box” that would limit our range of options. cplace, with its Shared Source approach, is a positive exception in this market.

Complex Project and Portfolio Management in Mechanical Engineering

As a highly specialized industry requiring technical expertise, complex processes, and innovative solutions, the mechanical engineering industry faces unique challenges in implementing successful projects. From planning and design to execution and implementation, companies must be able to maintain an overview, optimize resources, and control time and cost management.

Challenges

Complex projects

Designing and manufacturing machines requires close collaboration with departments that have specialized knowledge in each area. Coordinating and integrating these different components can be a major challenge, especially when changes or adjustments are required during the course of the project.

Time and cost management

In mechanical engineering, schedules are often tight and budgets are limited. Project management must therefore ensure that the project is completed on time and within budget. This requires careful planning, monitoring, and management of resources to avoid delays and cost overruns.

Risk management

Engineering projects often involve various risks. Companies must therefore be able to identify potential risks at an early stage, assess them, and take appropriate measures to manage them.

What cplace Can Do for You

Collaborative project management

Complex schedules are structured by breaking down the overall project planning into arbitrarily detailed and interlinked sub-plans. These sub-plans are linked via a common database and enable the delegation of decisions and their execution across plans and companies.

Improved resource planning

cplace helps to effectively plan and utilize resources such as manpower to ensure that projects can be completed within the planned budget and schedule.

More flexibility

With cplace, employees can design their own digital work environment in which they like to work. Changes and adjustments can be made without programming knowledge. cplace also offers integration options in the existing system landscape.

Reduced risks

Potential risks such as cost overruns, delays, or quality problems are identified at an early stage through cplace’s risk assessment and can thus be minimized.

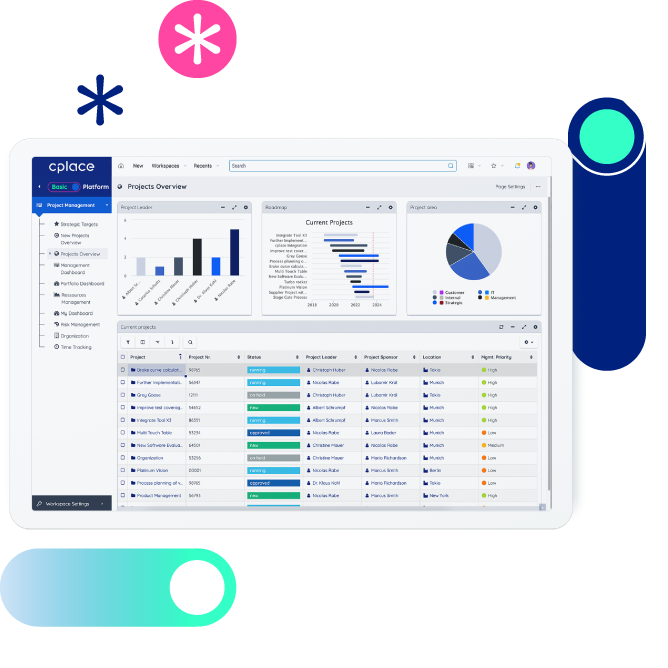

Product Highlights

Cross-Company Planning

cplace CCP enables cross-company collaboration in multi-tier supply chains. External partners and suppliers can be securely integrated into the company’s own planning process.

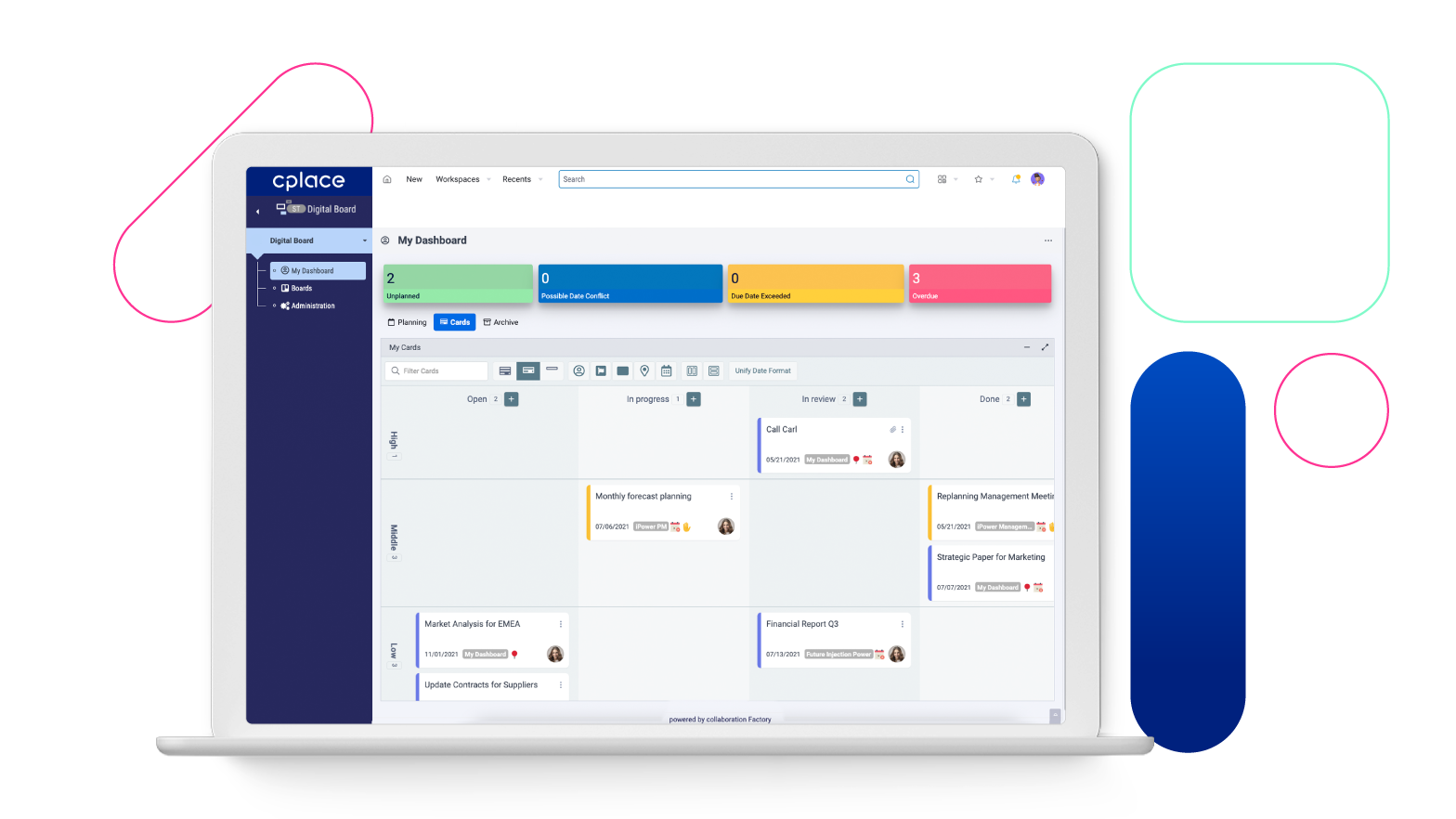

Individual dashboards

cplace enables users to see exactly the view of data that is relevant to them and displays information depending on the user role, e.g., as a milestone in a Gantt chart.