Resilient and Crisis-Proof Supply Chain

Thanks to LOOMEO Supply Chain Risk & Allocation Management, supply and demand can be balanced quickly and customer needs can be fulfilled in a targeted manner.

Make an expert appointment

LOOMEO SCRM seems groundbreaking compared to other SCRM products I have seen so far and is a reference for me. My compliments!

Challenge

The current supply and material crises confront companies with enormous challenges: In most cases, they work in historically grown supply networks that are not designed for optimal cost or risk design. End-to-end transparency in the supply chain is missing. It is hardly possible to forecast the detailed impact of a supplier’s failure on the value creation process. The lack of resilience in supply chains, combined with strong fluctuations in demand and the current crises, is leading to critical shortages. The required data is distributed among different people and systems in the company and can therefore only be used to a limited extent, as relationships are not recognisable. This forces those responsible to act purely reactively in task-force mode in order to deal with urgent challenges.

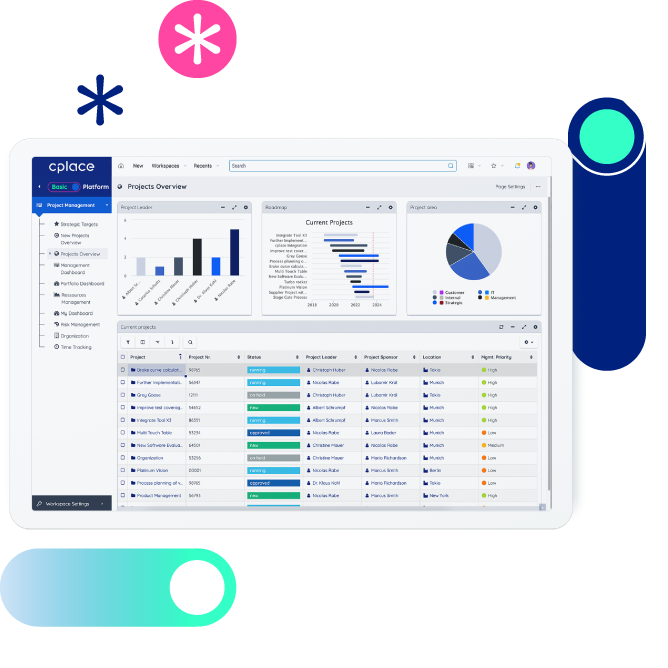

cplace Solution

The optimal distribution of scarce materials is critical to the success of manufacturing companies. Thanks to LOOMEO Supply Chain Risk & Allocation Management, supply and demand can be balanced quickly and customer needs can be fulfilled in a targeted manner.

The solution enables comprehensive end-to-end visibility across global sourcing, production and supply networks. It also makes it possible to clearly determine the business-at-risk in the event of failures in the supply chain. Using predictive analytics, LOOMEO supports the development of a risk model and the early detection of structural weaknesses for preventive supply chain improvement.

Involved Partners

Highlights

Automatic use

Optimal distribution of scarce material thanks to advanced algorithms and AI

Visualisation of effects and impact analysis

Rapid identification of the effects of a failure along the supply chain

Business at Risk

Quantitative evaluation of the extent of damage using various key figures

Cluster-Risk value

Preventive identification of risk hotspots in the supply chain based on risk scores

Collaborative risk reduction

Collaborative, cross-functional work on improvement measures in the Kanban Board

End-to-end overview

Complete transparency of the demand and supply situation with graphical inventory progression